BMW E46 M54B30 Engine build

17th Oct 2018

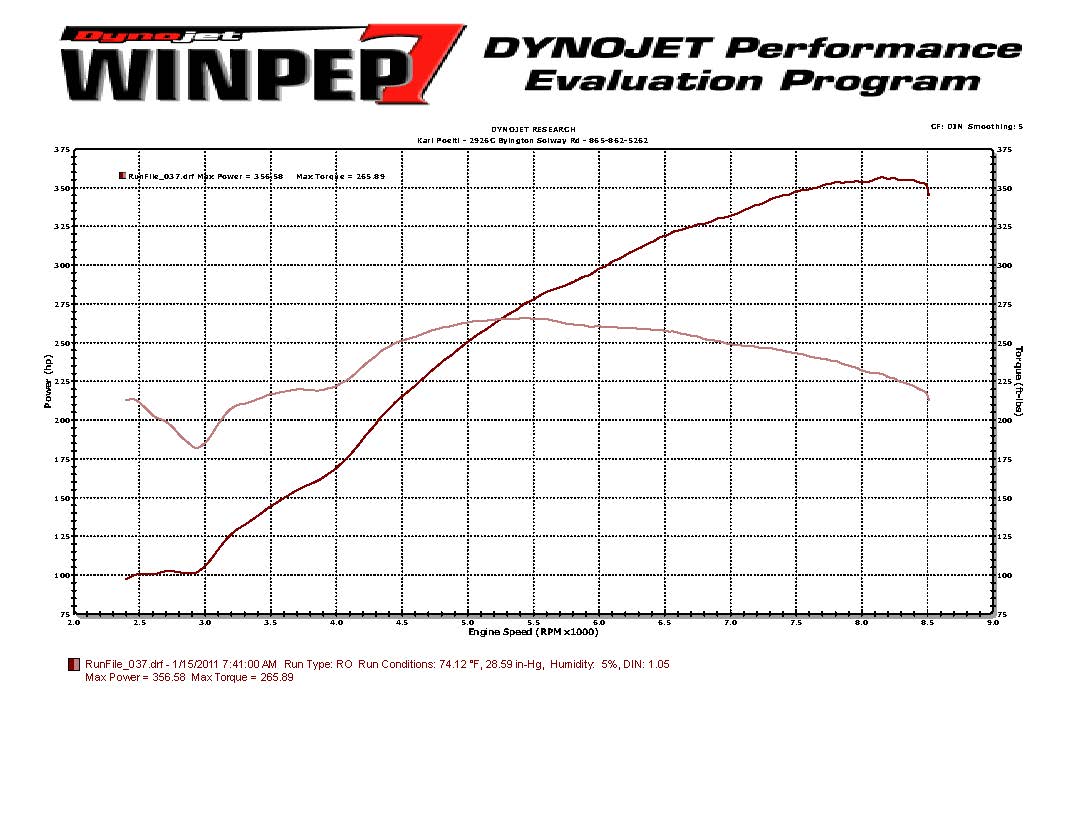

We set out to get as much power as possible out of a normally aspirated E46 M54 3 liter engine with a stock bore of 84 mm so that the car could run as a DM in BMW club racing or in NASA GTS4 . We decided we would build a high compression engine with big cams, larger intake valves with forged pistons and Rods. Of course we chose Wossner Pistons and had them custom made to get exactly what we wanted. With German precision and attention to detail the end result is really special. The engine made 354 HP at the rear wheels (an estimated 425 hp at the crank). Take a look at the dyno graph below,.. pretty sweet. We tuned the intake runner length to give us the best HP curve we could achieve. The engine is Motec M600 controlled and uses the VANOS intake cam control to keep the torque curve up as high as possible for as long as possible. The tuning was done by Ed Senf who is well know for tuning race BMW engines..

The side of the M54 head is angled so we had to make a custom adapter to use the intake system we wanted. We used a FARO arm to take all the measurements we could and then constructed a 3D model of the intake face of the head. Using the model allowed us to design an adapter so we could mount the E46 M3 Individual throttle bodies to the side of the head. It came out really clean and everything mounted up perfectly.

This really opened up the breathing for this beast of an engine. We custom made a large volume intake air box with a large front opening so the engine would never be straining to get air.

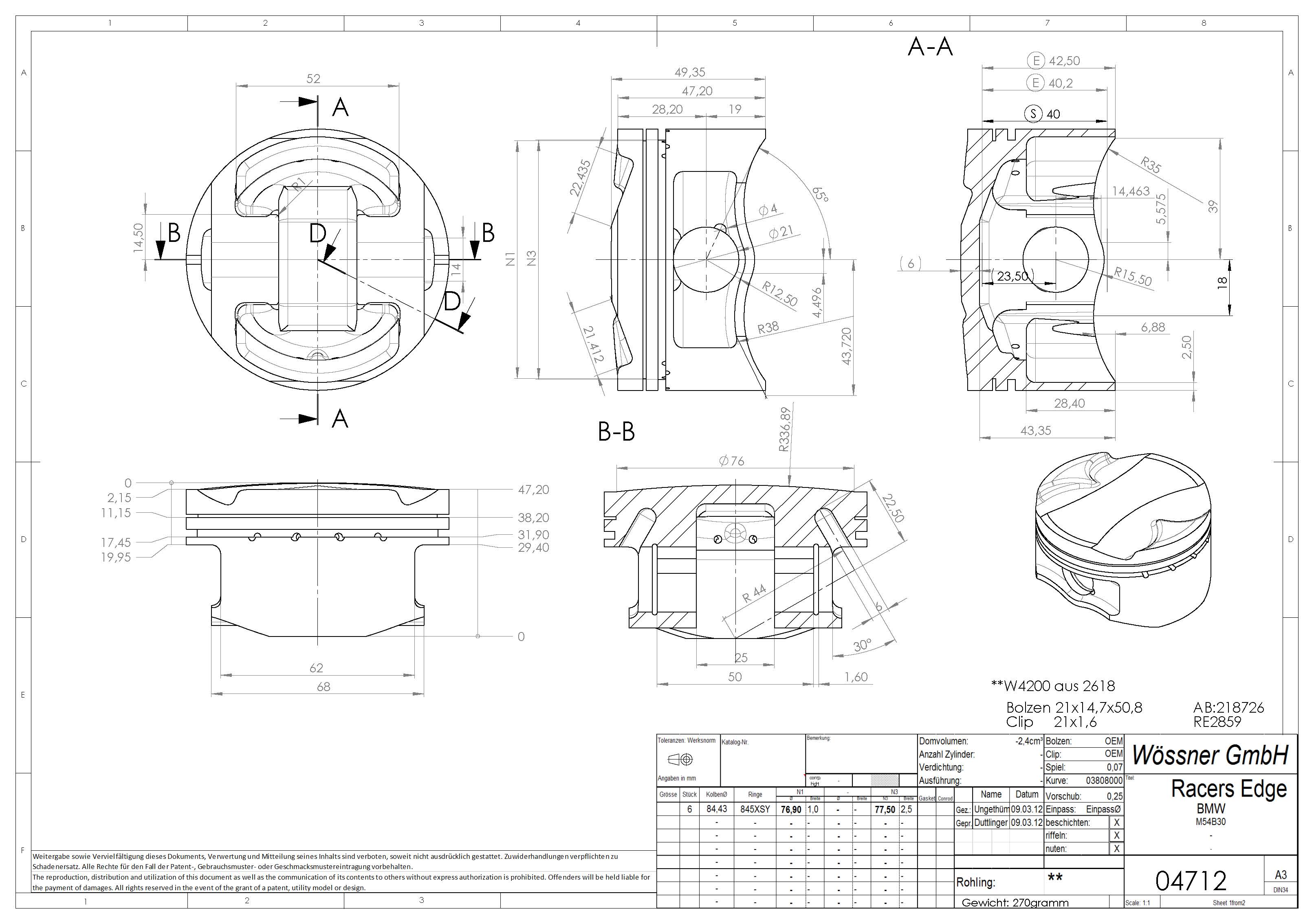

For the basic design of the engine we targeted a 13:1 compression ratio with a red line of 8500 RPM We us an ATI front damper to help keep it all together. The dome volume needed to achieve the desired 13:1 with our design was 2.4 cc. Check out the design Wossner came up with,.. single compression ring to get the most power out (less frictional loss). We also use dry sump lubrication with a 4 stage Auto Verdi pump and a 5 gallon Peterson tank. The dry sump pulls a significant vacuum so we had the special wrist pins coated with DLC to avoid any possible oiling issues with the wrist pins, We also DLC coated the Cams to try and steal every HP we could away from friction loss. For the oil itself we use the Millers CFS 10w40 NT+ which we think is the best there is and has the lowest coefficient of friction of all the oils we tested,.. and we test an bunch.

The end result was a pretty fantastic approximate 425 crank HP. And it all started with the fabulous Wossner custom pistons.

.